Thai Oil Public Company Limited (SET: TOP) has called for an Extraordinary General Meeting of Shareholders to consider approving an increase of the investment cost in the Clean Fuel Project (CFP) that has been delayed due to main contractor issues for a total amount of 63 billion baht.

In a letter disclosed through the Stock Exchange of Thailand, TOP states that its Board of Directors approved to convene the Extraordinary General Meeting of Shareholders on 21 February 2025 to consider and approve an increase of the investment cost in the Clean Fuel Project in the amount of approximately THB 63,028 million or approximately USD 1,776 million and the interest during construction of approximately THB 17,922 million or approximately USD 505 million equivalent.

The CFP Project investment was approved on August 27, 2018, with an estimated value of USD 4,825 million or THB 160,279 million. Construction completion was initially expected by the first quarter of 2023, with contracts awarded to notable main contractors, comprising Samsung E&A (Thailand) Co., Ltd., Petrofac South East Asia Pte. Ltd. and Saipem Singapore Pte. Ltd. in a joint venture known as UJV.

The project’s cost increased significantly, including an additional USD 422 million in interest during construction and a USD 550 million budget increase for further development. The completion timeline was extended by 24 months to ensure project success in the best interest of the Company.

TOP notes that the completion of CFP would be beneficial to the company as the project aims to upgrade the crude oil distillation capacity from 275,000 to 400,000 barrels per day, allowing for greater economic efficiency. This capacity boost is supported by advanced refinery technology, enabling the processing of various crude types, including cost-effective heavy crude, while enhancing high-value, environmentally-friendly product output. The upgrade is vital for improving the firm’s competitiveness and stability within the petroleum refinery sector, contributing to the nation’s energy security and economic growth.

However, the completion of this project hinges on increased investment. Without it, the company risks faltering competitiveness, tied to the limitations of the aging 60-year-old distillation units, which may struggle with advanced fuel production demands in the future market. Work delays caused by the Main Contractor’s financial difficulties necessitated a strategic review, revealing an additional investment requirement.

Based on insights from technical and legal advisors, and an independent financial advisor, the Board emphasized shareholder involvement by scheduling an Extraordinary General Meeting to approve this crucial investment decision, aligning with corporate governance and stakeholder interests.

TOP does not specify the source of fund for the additional increase in investment pending for shareholders’ approval, but reiterates that the increase would make the total investment in CFP to reach THB 241,472 million or approximately USD 7,151 million and the total interest during construction of approximately THB 37,216 million or approximately USD 1,078 million. The sources of funds used for the operation of the CFP Project will consist of, 1) existing debt instrument and loans 2) liquidity management and seeking of future fundings from the issuance of debentures and/or loans from commercial banks, as well as, alternative non-debt Instruments and 3) the rest of the funds will be obtained from the remaining cash balance and cash flow from the Company’s future operation.

As for the risk of increasing investment costs, TOP is well aware of the matter, stating that the CFP Project is a complex project in terms of construction and technology, any change of contractor during construction may result in project management discontinuity and increase in investment cost and longer period of construction of the project.

Additionally, TOP states that in the event that the shareholders do not approve the increase of investment cost in the CFP Project, the Company will need to coordinate and expedite the Main Contractor to pay overdue payments to subcontractors and perform their obligations as per the EPC Contract.

At present, the Company is in the process of resolving this issue by sending letters urging the Main Contractor and their parent companies to settle overdue payment to subcontractors, and the Company is also closely monitoring impacts to carefully determine a proper course of actions as well as enforcing and protecting the Company’s rights under the EPC Contract, prioritizing the best interests of the Company and its shareholders.

However, if the shareholders do not approve the increase in the investment cost of the CFP Project, the Company will not be able to complete the construction of the CFP Project as per its objectives.

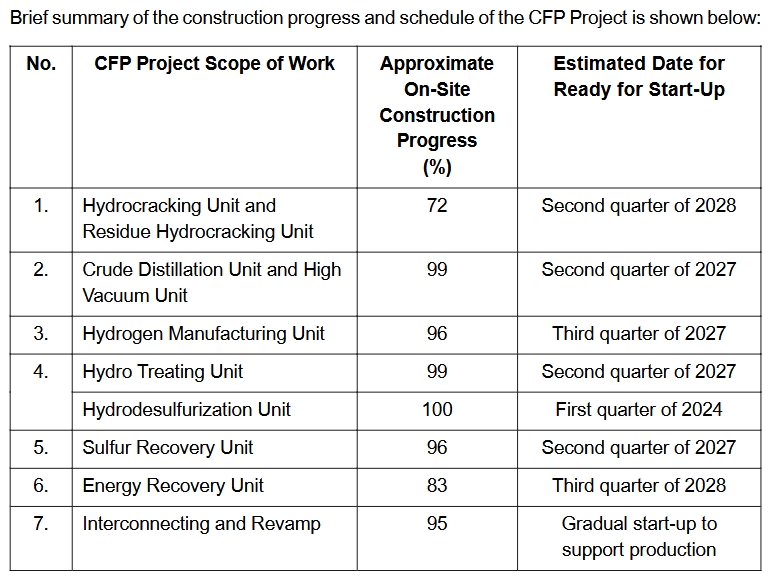

TOP adds that it has reviewed and evaluated the plan in collaboration with a technical expert on conservative basis and concluded that the commercial operation of the CFP Project is expected to commence by the third quarter of 2028.

Overview of CFP Project

The scope of the CFP Project comprises of the construction of six groups of refining operation units as follows:

Group 1: Hydrocracking Unit (HCU-3) and Residue Hydrocracking Unit (RHCU), which are refining operation units that help adding value to the products by converting fuel oil and bitumen to middle distillate fuels, i.e., jet fuel and diesel.

Group 2: Crude Distillation Unit (CDU-4) to replace CDU-1 & CDU-2 with the refining capacity of 220,000 barrel per day, which distill crude oil, and High Vacuum Unit (HVU), which distill Long Residues oil from the residues of crude oil distillation columns of CDU-4 to be processed to feed to other units for further value adding.

Group 3: Hydrogen Manufacturing Unit (HMU-3 / PSA-4), which produces hydrogen for the use in other distillation units.

Group 4: Hydro Treating Unit (HDT-4) and Hydrodesulfurization Unit (HDS-4), which extracts sulfur from benzyl and diesel oil content, respectively.

Group 5: Sulfur Recovery Unit (SRU), which produces sulfur extracted from various types of oil by the Hydro Treating Unit, before distribution in the form of liquid sulfur or converted into solids for export purposes.

Group 6: Energy Recovery Unit (ERU), which extracts the residual products from converting of heavy oil into jet fuel and diesel from RHCU, referred to as “pitch”, to be used as the fuel for generating electricity which will be used in the production units of the CFP Project.

At present, The Hydrodesulfurization Unit 4 or HDS-4 construction has been successfully completed and commenced test-run for the production of Euro 5 Standard diesel in February 2024.